A1: the main board power supply of the turnstile is 24V, and the controller power supply is 12V.

Be careful when wiring to the transformer , otherwise it is easy to burn the machine.

A2: two FR1200 shall be connected in parallel.

The dial switch two FR1200 needs to be set differently, such as 1 and 3 or 2 and 4. This is because if the dial switch is same , it will be considered as the same fr1200, resulting in that the turnstile can only enter in one direction.

A3: the connection port between two Wiegand read heads and controller reader is:

Reader1 and reader3, reader2 or reader4

This is because the turnstile is bi-directional and we think it is controlled by two different doors.

And Reader1 and reader2 control gate 1, reader3 and reader4 control gate 2, so you need to wire in this way.

A4:K1 ——NO(LOCK1)

GND ——COM

K2 ——NO(LOCK2)

GND ——COM

A5:SEN———black

SEN+ ——red

SEN3 ——purple

SEN2 ——blue

SEN1 ——green

SENC3 ——yellow

SENC2 ——orange

SENC1 ——brown

A6: it's related to the mechanical design and construction. When there is power, the controller does not send a signal to the turnstile main board to ensure

The turnstile does not trigger the electromagnetic switch, so as to ensure that the turnstile can not pass through.

If the NC terminal is connected, the controller will send a signal to the main board of the turnstile to promote the turnstile . The main board of the roller gate triggers the electromagnetic switch, so that the turnsitle can pass through without swiping the card all the time.

A7: Our turnstile has the function of automatic rod dropping in case of power failure and manual rod loading in case of power on.

After the power is restored, wait for more than 6S and lift the brake lever manually.

A8: the problem should be power and wiring.

Check whether the connecting wire and power wire from the central control end to the lamp board are damaged, and whether the terminal block is loose, etc

A9: This problem should be the problem of parts and dropping pole electromagnet.

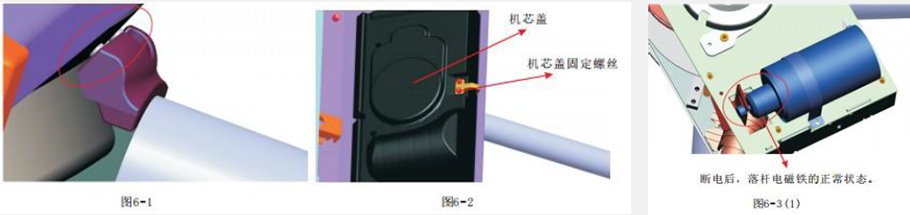

1. Check whether the upper lever time limit seat is against the rotary table, as shown in Figure 6-1.

2. Check whether the falling bar magnet works, open the upper cover of the chassis, and open the core cover with a hexagon screwdriver (Fig. 6-2)

Check the working state of the electromagnet, as shown in Figure 6-3.

Post time: Mar-10-2020